Usages

Field inspection solved

If you need to keep track of your asset inspections offshore, somewhere off-grid, on a vessel in transit or on any other industrial facility on land. Inspectio can help you.

Our most popular usages

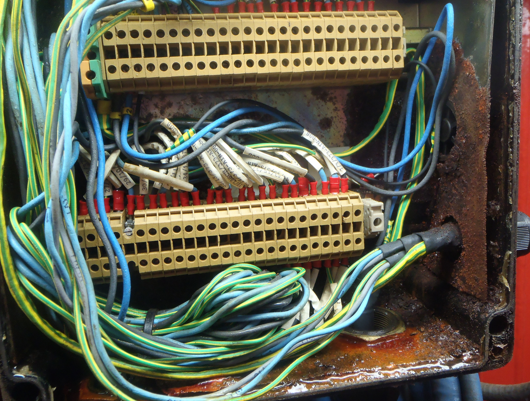

Ex equipment, electrical utilities such as junction boxes and light fixtures used in areas where explosive gasses may occur, is subject to frequent inspection needs, and many asset owners find it hard to complete the scheduled inspection campaigns planned in their maintenance system. Especially if the number of equipment units needing inspection is large.

The reasons for this struggle are multifaceted and include manpower, prioritization, lack of an overview of equipment locations, poor procedures, and inadequate inspection methods. Hiring an inspection provider may help you complete these inspection tasks on time, is a good way of getting things done, but it does not tackle the core issues of time constraints and lack of procedures for executing inspections.

With the Inspectio software solution, we can offer peace of mind, complete equipment database & integrity control, and the industry’s most efficient way to collect field data. Guided by Inspectio, our proprietary Task Engine manages the complexity of Ex inspections, enabling inspectors to easily perform their job with the correct task template.

Hoses, those black rubbery items essential to powering many heavy tools in the industry, are often neglected. They are typically either replaced when broken or when a predetermined lifetime limit is reached. Either way, maintaining a database with each hose’s installation date and properties is crucial.

However, implementing such a system has proven easier said than done, leaving asset owners with a third option: replace all hoses at a fixed interval regardless of their installation date. This approach wastes resources, as perfectly good hoses may be discarded. It is easy to justify this method by saying it’s cheaper than experiencing equipment downtime. Although this may be true, it shouldn’t prevent you from performing daily or campaign-based integrity inspections of your hoses. We argue that the “replace all” approach further neglects day-to-day hose integrity monitoring.

With the Inspectio software solution, we can offer peace of mind, complete equipment database & integrity control, and the industry’s most efficient way to collect field data. Guided by Inspectio, our proprietary Task Engine manages the complexity of Hose inspections, enabling inspectors to easily perform their job with the correct task template.

Cable transits are important! You may not think much about them in your day to day job, but they exist for good reasons. A cable transit make sure that when routing cables through steel walls, the transit from one side to the other is air, water and gass tight.

There are no international standard today of how to identify or verify if a cable transit is correctly installed. It is usually left unattended, or outsourced to an expert service contractor. Obvious damages are found by operators, and action can be taken, but the was majority issues, such as wrong installation and a following loss of integrity is hidden from the untrained eye. When was the last time you verified that your cable transits does their job? Have you documented that you did?

With the Inspectio software solution, we can offer peace of mind, complete equipment database & integrity control, and the industry’s most efficient way to collect field data. Guided by Inspectio, our proprietary Task Engine manages the complexity of Cable transits, enabling inspectors to easily perform their job with the correct task template.

Portable equipment such as radios, handtools and flashlights must be verified safe to use. Depending on where the equipment is used, different regimes for inspection, pre-use check etc is mandatory. You may not alway know where your portable equipment is located, but you should know that it has been inspected and integrity verified by a trained person at planned intervalls, beore your own pre-use check.

With the Inspectio software solution, we can offer peace of mind, complete integrity control, and the industry’s most efficient way to collect field data. Guided by Inspectio, our proprietary Task Engine manages the complexity of Portable equipment, enabling inspectors to easily perform their job with the correct task template.

If you have clicked through our most popular use cases, you know understand that Inspectio offers a general and flexible database and field app that can cover any inspection need. Challenge us today!